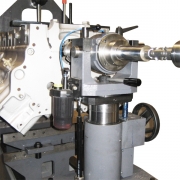

BAC1500

The BAC series of align boring machines deliver a superior accuracy and reliability for successful align boring of main and camshaft bearings. The base castings are exceptionally heavy to eliminate any possibility of deflection, and the drive shaft is particularly sturdy and has an exceptional working force. The low voltage electrical system is designed as per the latest safety standards. The lubrication system is very simple and rational. The manual working feed has a quick or micrometric control and the automatic working feed has variable speed in both directions. The boring bar holder supports are adjustable vertically and horizontally. Workholding fixtures deliver superior performance and are designed to minimize the chances of errors in set-up. All controls are easy to understand and to use. They are placed in a convenient position, allowing the operator easy access when standing near the workpiece

{tab=VIDEO}

{youtube}Gof6gOn4Mpw{/youtube}

{tab=SPECIFICATIONS}

BAC1500 | BAC2000 | BAC2500 | |

WORKING CAPACITY | |||

| Max length of block | 1500 mm | 2000 mm | 2500 mm |

| Min e max boring diameter | 23-200 mm | 23-200 mm | 23-200 mm |

| Maximum spindle travel | 400+120 mm | ||

GEOMETRIC FEATURES | |||

| Min distance from bed to centerline | 450 mm | 450 mm | 650 mm |

| Max distance from bed to centerline | 650 mm | 650 mm | 850 mm |

SPEEDS AND FEEDS | |||

| Variable spindle speed | 100-600 mm/min | ||

| Continuos automatic feed | 0-80 mm/min | ||

Italiano

Italiano