Fully Automated Solutions

for Crankshafts-Camshafts Grinding

// FULLY AUTOMATED

// FOR LARGE AND SMALL PRODUCTION BATCHES

// ORBITAL GRINDING TECHNOLOGY

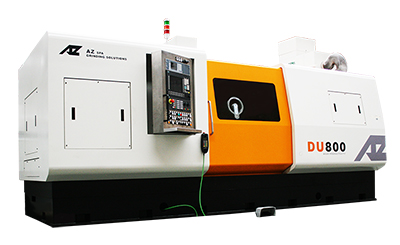

DU

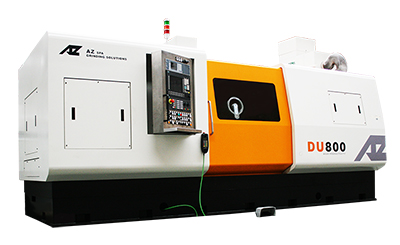

DUA

Fully Automated Solutions

for Crankshafts-Camshafts Grinding

// FULLY AUTOMATED

// FOR LARGE AND SMALL PRODUCTION BATCHES

// ORBITAL GRINDING TECHNOLOGY

DU

+ LARGE BATCH PRODUCTION

+ SINGLE OR DOUBLE WHEELHEAD CARRIAGE

+ BASE MADE OF COMPOSITAL

+ WHEELHEAD MOVES ON X and Z AXIS

This machine model has been designed for high production batches, the machine can be equipped with a double wheelhead carriage with two wheels that can work simultaneously. The DU base is made of a composite material of concrete and steel specifically designed to obtain the best result between structural deformations and natural frequencies allowed.

DUA

+ SMALL BATCH PRODUCTION

+ SINGLE WHEELHEAD CARRIAGE

+ BASE MADE OF CAST IRON

+ WHEELHEAD MOVES ON X AXIS-TABLE MOVES ON Z AXIS

The DUA version has been designed for lower production batches than the DU model. The machine mount a single wheelhead carriage. The DUA has the following machine configuration: compared to the DU model, the table moves along the Z axis and the wheelhead moves along the X axis, with a “T” shape cast iron base.

+ LARGE BATCH PRODUCTION

+ SINGLE OR DOUBLE WHEELHEAD CARRIAGE

+ BASE MADE OF COMPOSITAL

+ WHEELHEAD MOVES ON X and Z AXIS

+ SMALL BATCH PRODUCTION

+ SINGLE WHEELHEAD CARRIAGE

+ BASE MADE OF CAST IRON

+ WHEELHEAD MOVES ON X AXIS-TABLE MOVES ON Z AXIS

This machine model has been designed for high production batches, the machine can be equipped with a double wheelhead carriage with two wheels that can work simultaneously. The DU base is made of a composite material of concrete and steel specifically designed to obtain the best result between structural deformations and natural frequencies allowed.

The DUA version has been designed for lower production batches than the DU model. The machine mount a single wheelhead carriage. The DUA has the following machine configuration: compared to the DU model, the table moves along the Z axis and the wheelhead moves along the X axis, with a “T” shape cast iron base.

Italiano

Italiano